At the center of the CNC lathe is a computer Regulate system. This system makes use of preprogrammed program to direct the machine’s movements. The instructions tend to be prepared in G-code, a standardized programming language for CNC machines.

Toolroom lathes will be the unsung heroes of precision machining, able of producing complex parts with limited tolerances. These machines are made for high-precision jobs, where by the margin for mistake is almost non-existent.

Variable speed headstocks are equipped with adjustable pace Handle mechanisms, letting operators to change the spindle velocity easily.

These Keeping products ensure the workpiece continues to be firmly positioned, letting for correct and regular machining functions.

This was accompanied by gantry loaders for chuck machining. Currently, holistic automation solutions including the Robo2Go styles, the MATRIS light as well as the IMTR complete DMG MORI’s portfolio for employing totally automatic processes in turning and turning/milling.

The large number of variants, miniaturization and precision with the workpieces are but a few of the demands with a CNC swiss turning centre. The TNL-sequence is characterized by high general performance in combination with simple set up and programming.

This set up is ideal for parts that demand machining on both equally finishes. Through the use of twin spindles, you may decrease setup situations and raise production charges.

Our instruct lathes are designed with solid, steady, and wider bed way for maximum vibration absorption. The entire mattress features superb structural rigidity. Dovetailed carriage and cross slide are hardened, high precision ground, coated with Turcite-B and scrape completed to be sure uniform surfaces.

Aggressive Benefit: Organizations that utilise sliding head lathes gain a competitive edge by providing high-good Swiss CNC system quality, precision-engineered factors with shorter guide moments.

This then enables functions to get carried out to the Formerly unreachable back with the component. As soon as the section is finish, this spindle then deposits the element right into a section receptacle.

The headstock’s flexibility extends to tapping functions, enabling the development of threaded holes from the workpiece. By using appropriate tooling, the headstock helps create threads of varied measurements and pitches, improving the features and versatility from the manufactured parts.

Reduced materials Wastage: The look of sliding head lathes permits the successful usage of barstock with negligible remnant and exceptionally very low ingredient reject prices. This is very useful when working with high priced or unique components.

CNC lathes advanced from manually operated lathes. The introduction of computing controls in the 1940s and 1950s transformed them into the automated powerhouses we use today.

By leveraging the advantages of CNC lathes, it is possible to Increase the good quality, pace, and price-performance of your producing operations. Allow TMC Technologies be your associate in achieving precision and effectiveness in the generation processes.

Josh Saviano Then & Now!

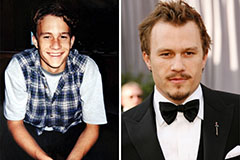

Josh Saviano Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! Joshua Jackson Then & Now!

Joshua Jackson Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now! Peter Billingsley Then & Now!

Peter Billingsley Then & Now!